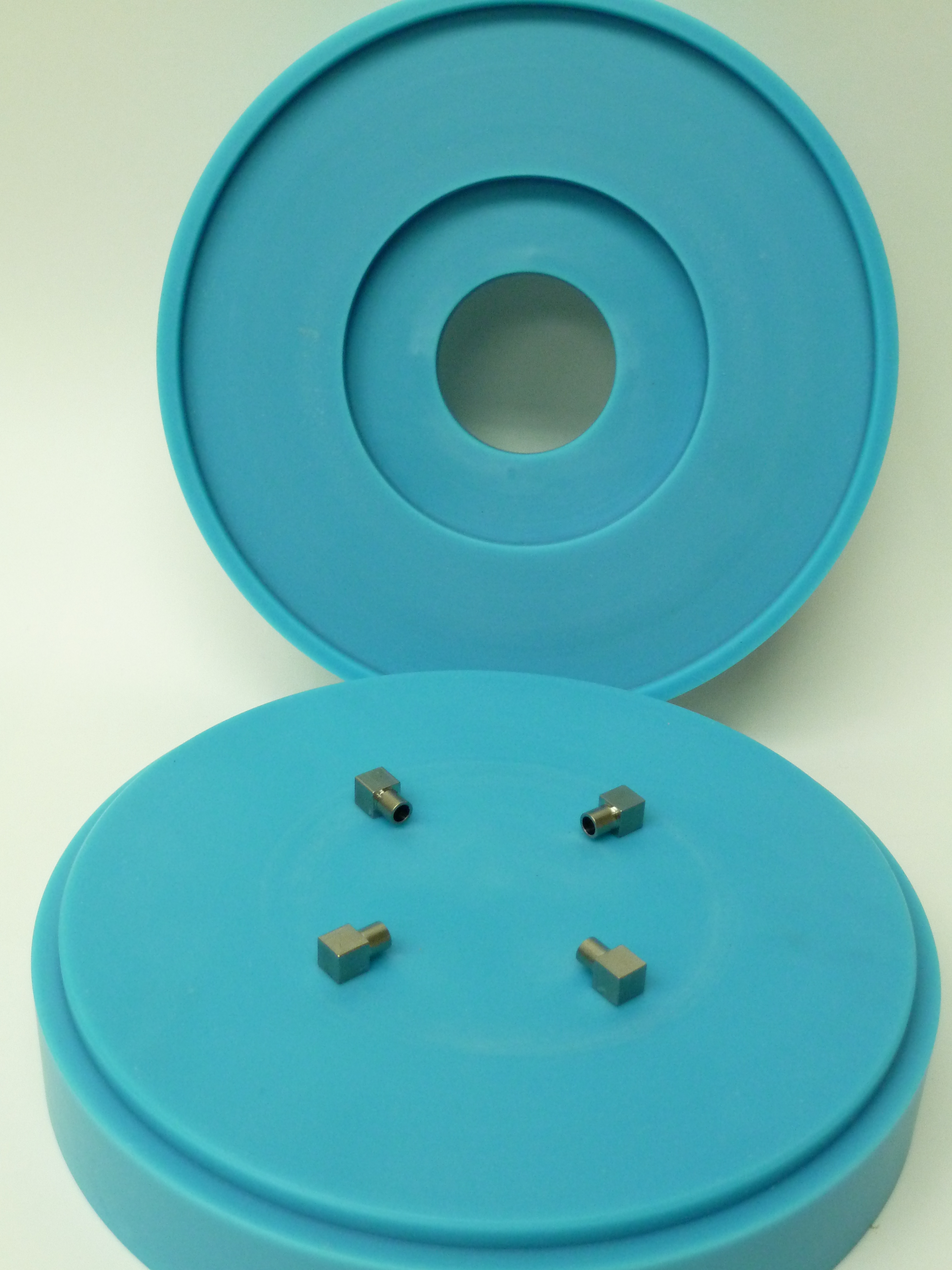

Valves, fittings, glands, tube fittings and other components used in semiconductor manufacturing must be finished to extremely high finishes to minimize or eliminate contamination. Abrasive Flow Machining (AFM) polishing of the internal, wetted surfaces of high purity components will provide mirror like finishes as down to 5 μinch Ra. The combination of AFM polishing of the machined or drawn internal surface followed by electropolishing to provide the correct chrome to iron ratio at that surface meets the stringent standards for contamination control required by the semiconductor and also the pharmaceutical industries.